THE ENERGY AND POWER DENSITY IN BATTERIES CAN BE INCREASED BY RE-EXAMINING THE ARCHITECTURE.

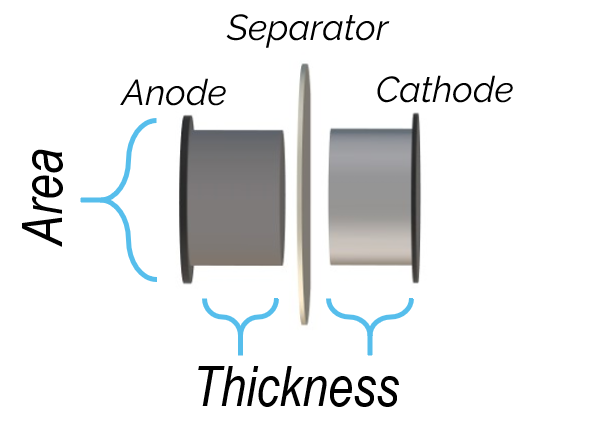

Batteries are traditionally based on 2D stacks of Cathode (+) and Anode (-) materials with an Electrolyte Separator

An example of a 2D battery layout

The two critical factors of battery architecture are the surface area and the effective thickness of the active material.

SURFACE AREA

The energy in a battery is based on the total area of the cathode and anode that connects to the metal contact.

More electrode area means more available electrons, and, therefore, more energy.

DENSITY

The power out, or charge time of a battery, is determined by the thickness of the active material.

Thinner electrode material allows electrons to move faster from the material to the device being powered so more power is available or faster charging times are safely achievable.

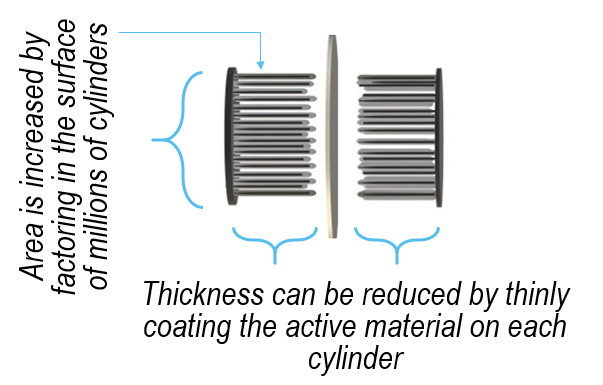

SIENZA ENERGY'S PATENTED TECHNOLOGY FULLY UNLOCKS A NEW DIMENSION IN BATTERY ARCHITECTURE...

Sienza Energy’s technology offers a superior solution that provides more energy and power density.

Sienza’s patented technology, developed in the labs at Caltech, is not simply a modification, refinement, or incremental improvement of current battery materials or processes. Unlike conventional lithium batteries which utilize millions of micron-size particles of active materials per square centimeter compressed and bound together with a polymer to make an electrode, Sienza’s technology uses billions of individual 3D nanostructures to form the electrode architecture. This provides about 100 times the surface area available for chemical reaction, which greatly increases both the power capability and energy available from the active materials.

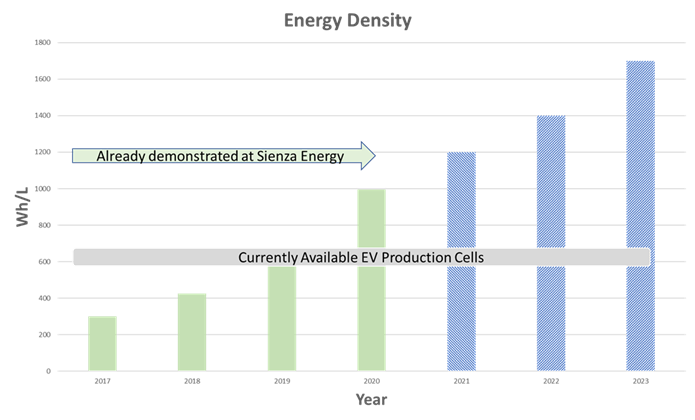

The patented Sienza Energy architecture can allow:

Energy Density of 1,250Wh/L and Power Density of 7,800W/L when optimized to be in a single battery

Or if optimized separately:

Energy Density of 1,700Wh/L for an energy-dense battery

Power Density of 15,900W/L for a battery that acts like an energy-rich super-capacitor

…WITH ROOM TO GROW.

Sienza Energy’s patented technology is a new approach that is not chemistry dependent.

Our revolutionary manufacturing method is a breakthrough and has opened new ways to synthesize new chemistries at low temperatures. Cathode materials synthesized using this technique could potentially store 3 to 5 times more energy than current cathode materials. This will lead to a battery with a cell-core energy density of 2,000Wh/L or about 1,700Wh/L in a full-size EV battery—more than double the best current technology!

This revolutionary approach is not tied to a particular battery chemistry. As new chemistries are explored, they can be applied to this architecture, instantly improving effectiveness, as well as energy and power levels.

THE KEY BENEFITS OF SIENZA ENERGY'S 3D NANOSTRUCTURED ELECTRODES

Enables increased thicknesses of electrodes which provides higher energy density (Wh/L) without compromising the power density (W/L)

Enables increased thicknesses of electrodes which provides higher energy density (Wh/L) without compromising the power density (W/L)

Enables high loadings (mg/cm2) of active materials

Enables high loadings (mg/cm2) of active materials

Provides very stable and very high areal capacity with a 100% Silicon anode

Provides very stable and very high areal capacity with a 100% Silicon anode

Provides both higher energy density and significant cost reduction

Provides both higher energy density and significant cost reduction

Eliminates the use of binders and carbon additives

Eliminates the use of binders and carbon additives

Provides flexibility to use all anode and cathode chemistries

Provides flexibility to use all anode and cathode chemistries

We have already built hundreds of cells with a number of different anode and cathode materials during the past two years.

SUSTAINABILITY

Sienza Energy can Energize the World in a Responsible Way

Sienza battery technology offers a truly green lithium-ion battery at significantly reduced production costs and with little or no environmental impact.

Current lithium-ion batteries harm the environment by using dangerous materials such as cobalt, which is highly toxic and leads to several deaths every year. In addition, conventional lithium-ion manufacturing processes employ a solvent-based slurry mixing/coating method, generally using large quantities of toxic and expensive organic solvents such as N-methyl-pyrrolidone (NMP), a known reproductive toxicant. Sienza technology can use little or no cobalt in the cathode, and our dry manufacturing process eliminates the use of any toxic organic solvents.

THIS ARCHITECTURE IS ALSO MORE COST EFFECTIVE

This approach removes the needs for capital intensive, billion-dollar mega factories. More precise manufacturing equipment already in the marketplace is used to efficiently and rapidly grow active material needed for the battery. This lowers cost and increases throughput.

Sienza’s estimated cost ($/kWh) for manufacturing EV cells with our 3D nanostructured electrode technology is about half the cost of the current EV battery cells. This reduced cost and higher energy density (Wh/L) will offer EV car manufacturers the flexibility to build vehicles having both longer ranges and lower prices with smaller batteries.

Comparison of Sienza vs. Current EV

Cost and Volume Savings for the Same Range

-

48% lower battery cell cost

-

Same vehicle range

-

46% smaller battery pack cell volume

Cost Savings and Range Improvement for the Same Size Battery

-

24% lower battery cell cost

-

60% longer vehicle range

-

Same size battery pack cell volume